The company Bracksiecker

On the ball with us

Bracksieker Draht provides you with an extensive, market-orientated range of products as a competent partner with more than 100 years of experience.

Our core skills lie in the production and distribution of all kind of wire. We provide you with the majority of products “Made in Germany”, supplemented by our subsidiaries in eastern Europe.

As a partner to the recycling industry, we take care of the strapping of raw materials that others regard as waste. We also supply

- Baling press wire / binding wire for baling presses

- Patented-coiled rings / bremer rings

- Loop wires and quick-link wires with customer-specific dimensions

Our other main focal areas include supplying to the construction industry, hot-dip galvanising plants or even agriculture with whatever kind of wire they need. Here, we provide you

- Binding wire rolls / binding wire mice

- Concrete binding wire

- Straightened rods according to customer requirements

- Production rings

- 60/80 rings

- Splited rings

We supply corrugated wire mesh “made in Germany” in standard sizes, but also manufactured to customer-specific dimensions.

Do you need fences and the right material? We can advise and supply you in a competent way.

We can also provide you with wire nails and nails in different variants.

On the track of wire

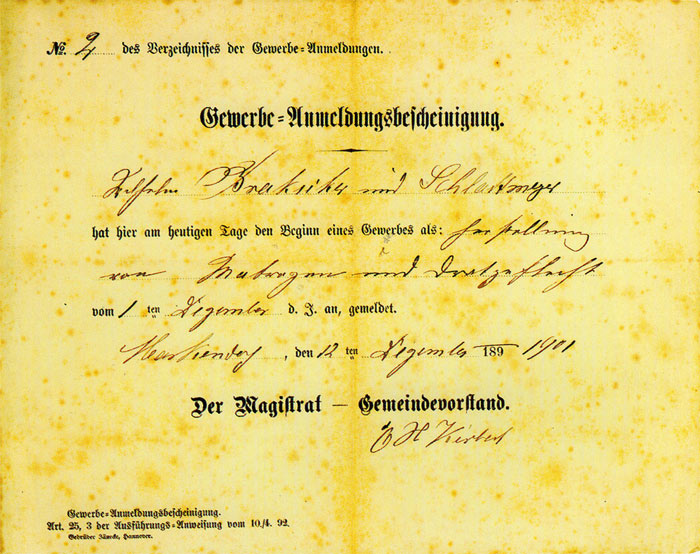

In 1901, founder Ernst Bracksieker, with the support of his father Wilhelm Bracksieker, started perhaps his greatest adventure by starting the production of mattresses and upholstery.

Just one year later, he started the production of wire mesh and barbed wire. Thanks to his great passion, reliability, innovative ideas and the support of his family, more and more new markets were opened up. The product line was also expanded by manufacturing wire nails and woven wire grids, also known as corrugated mesh.

After the early death of Ernst Bracksieker, his son Friedrich Bracksieker took over the company at just 18 years old. He had the same entrepreneurial spirit as his father and uncle. He set a course in the direction that the company is still following today:

Innovation, passion, reliability!

- or in other words: Always on the ball!

Because of Friedrich Bracksieker’s foresight, the main focus shifted from trading to the production of galvanised and soft-annealed wires in the form of baling press wire, binding wire and patented-coiled rings - also known as Bremer rings. The program was expanded by manufacturing loop wires and quick-link wires using modern, innovative machines. Even the production of corrugated mesh was expanded.

Mrs. Helga Eilert, daughter of Friedrich Bracksieker, has been the Managing Director of the company since 1973 and pushed ahead with a great deal of commitment and passion. International markets were opened up and trade business was expanded.

In 1992 Friedrich Bracksieker, with a proud 85 years in the top job, passed it on to his grandson Klaus Eilert.

In 1993 Klaus Eilert, son of Helga Eilert, stepped in as Managing Director of the family company. He ensures that the export and import business is expanded and production is brought up to the latest technical standards. By recycling waste, in particular paper, the recycling industry is becoming important in the wire business. There has been tremendous growth in demand for binding wire for baling presses. The demand for patented-coiled rings for packaging machines and loop wires for vertical presses is also on the increase. In order to have these materials in stock for the customers, the warehouse capacity was extended by approx. 1,200 square metres in 2011.

Bracksieker Draht celebrated its 100th birthday in 2001, and the entire workforce is contributing to also shape the wire industry over the next 100 years as a reliable and innovative partner.

An outlook

Bracksieker now employs approx. 30 highly qualified and committed employees.

More and more focus is being put on sustainability due to dwindling resources. Particularly the recycling industry is an aspiring industry. With our wire, we make a contribution to protecting the environment by making something new from something old without falling back on resources.

Our portfolio also includes straightened rods made from stainless steel or in annealed, galvanised or blank versions. These are often used in the agricultural sector, in galvanising plants or in industry.